Benefits of Inventory Counting: A Critical Part of Inventory Management

Implementing cycle counts as part of their inventory control system is significant for small business owners and online retailers. It improves their understanding of the inventory cycle, allowing them to accurately track inventory levels and meet customer demands, ensuring timely product delivery.

In this article, we’ll walk you through the inventory counting process and its benefits, cycle counting inventory including the benefits.

Contents

What is Inventory Counting?

Why is Inventory Counting Necessary?

6 Benefits of Inventory Counting

How Frequently Should You Perform Inventory Counting?

Make Your Inventory Counting Flawless with PayTraQer

FAQs

What is Inventory Counting?

Inventory counting assesses stock levels by manually tallying product quantities. This crucial inventory management step ensures precise record-keeping for businesses.

With a regular inventory cycle count within their inventory control system, businesses can easily track their stock count in the warehouse. Accurate counts enable them to locate items and understand their inventory in quantity and value.

Why is Inventory Counting Necessary?

Inventory counting is necessary for maintaining operational efficiency, customer satisfaction, and financial accuracy within a business. Let’s look into the various benefits of why inventory counting is essential:

Enhances Inventory Management: Accurate inventory counting allows for effective tracking across multiple sales channels, ensuring visibility of stock quantities and locations, even across different warehouses. This level of control is crucial for efficient inventory management and maintaining accurate inventory levels.

Improves Order Fulfillment & Shipping: Efficient inventory control and regular inventory counts are crucial to customer satisfaction. It enables timely identification of out-of-stock items and the possibility of faster shipping from alternative warehouse locations, thus avoiding delivery delays and enhancing client satisfaction.

Supports Cost Management: Inventory counting provides data that helps identify fast-moving and underperforming items. That allows businesses to make informed decisions about what to stock, controlling costs and reducing excess inventory.

Enables Strategic Planning & Forecasting: The insights gained from inventory cycle counting contribute to understanding market trends and customer preferences, allowing businesses to forecast demand more accurately and plan for sustainable growth.

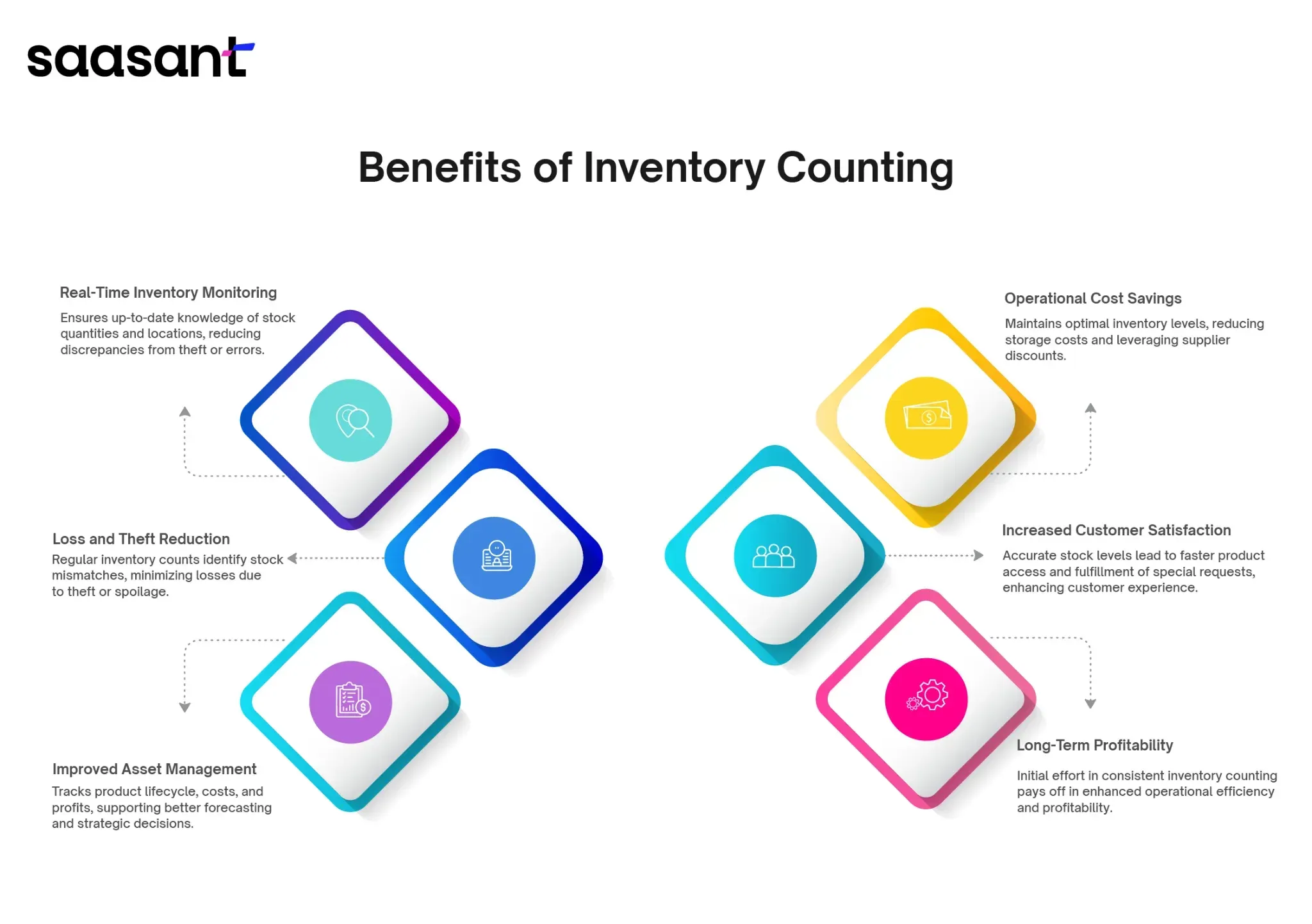

6 Benefits of Inventory Counting

Up-to-date monitoring & Documentation of Stock

Inventory counting helps you with real-time awareness of your product quantities and locations, guaranteeing that customers can consistently locate what they're searching for, whether in physical stores or online. This immediate knowledge of inventory levels helps you avoid any discrepancies from theft, incorrect orders, or other complications.

Having an accurate and regular count of your inventory positions can improve customer satisfaction and drive business growth. Precise inventory records help you identify top-selling items and those that might benefit from increased marketing efforts. This practice is a cornerstone of efficient inventory management, ensuring your business remains responsive to market demands.

Reduced Losses & Theft

With regular inventory counts, you can quickly identify any mismatches between inventory levels and actual stock. This approach significantly reduces losses attributed to theft or spoilage. Additionally, it helps to avoid the shelf space of overstocked products in inventory without contributing to sales.

Better Management of Assets

Inventory counts allow businesses to improve their asset management system, how long they stayed in storage, what was spent to acquire them, and how much profit was gained from each sale.

This collected data supports the development of forecasting models to plan for future customer demand by analyzing historical trends and seasonal variations in product availability.

Such insights enable small businesses to make strategic decisions about their product offerings, optimizing inventory levels to reduce costs while effectively meeting consumer needs.

Minimized Operational Expenses

Regular inventory checks ensure optimal stock levels, reducing unnecessary storage and operational expenses. Moreover, maintaining precise records of supplier purchases enables businesses to use their purchasing power for discounts or special deals on certain items, further enhancing savings.

Enhanced Customer Satisfaction

Maintaining accurate inventory levels helps you quickly access products that customers seek. This access boosts customer satisfaction by preventing delays caused by stock shortages or outdated pricing. Furthermore, precise inventory tracking allows businesses to accommodate particular customer requests more effectively, leading to increased engagement and repeat business.

Long-term Profitability

Counting your inventory might be challenging initially, but it has significant benefits. The counting method is accurate asset tracking, enhancing operational efficiency, which boosts long-term profitability.

How Frequently Should You Perform Inventory Counting?

Consider how frequently to count your inventory when evaluating your inventory management process. Also, find out which method best aligns with your business needs. Assessment frequency varies across businesses; some prefer monthly evaluations, while others prefer annual counts.

Base the decision on how often to conduct inventory audits on your company's historical performance and turnover rate. Smaller businesses with lower order volumes may not need frequent audits, whereas larger firms often implement automated systems. If you're managing inventory across multiple sites or field teams, a solution like Klipboard can help streamline mobile inventory tracking and reduce audit overhead with real-time visibility.

To ensure financial accuracy, we recommend conducting a comprehensive count at the end of each fiscal year, but it's also essential to seek advice from your accountant regarding timing.

Cycle counting

A cycle counting system in inventory management can save costs and enhance accuracy. This method is becoming the go-to for most businesses, as complete physical inventories are more prone to errors. With a well-implemented automated system, cycle counting becomes an efficient way to manage stock.

Automating the cycle counting process allows inventory accuracy checks without disrupting business operations. Conducting periodic spot checks throughout the year can further validate the effectiveness of this method, providing a clearer insight into real-time inventory management. Cycle counting offers numerous benefits, such as saving you a lot of time. For instance, while manually counting stocks, you may need to shut down your store and put in much effort. On the other hand, with this automated inventory process, you can also handle your store and manage stock counting.

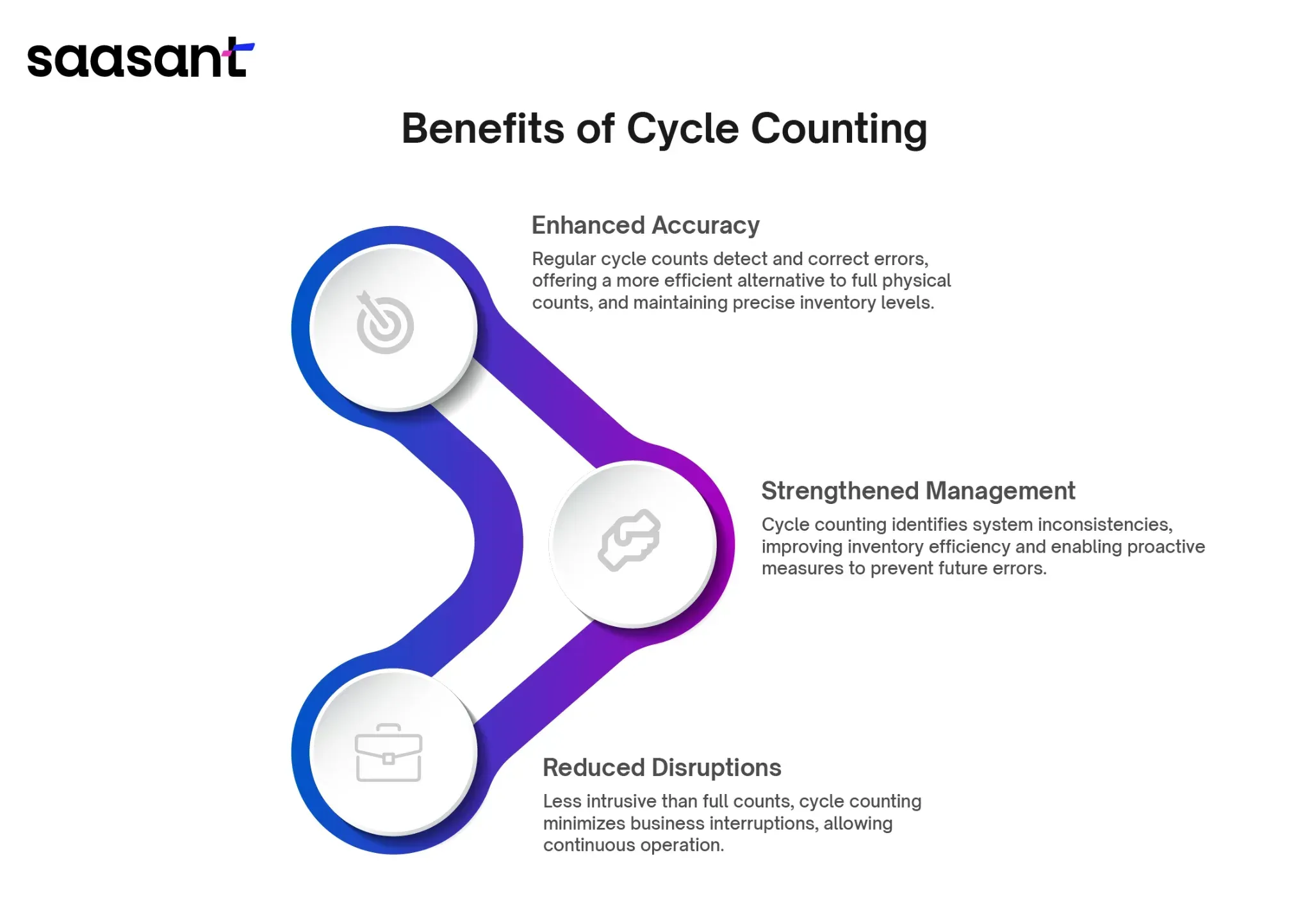

Benefits of Cycle Counting

Cycle counting offers various benefits over annual inventory counts. The benefits include accuracy, efficiency, identifying eros and rectification, cost-effective methods, etc. Let’s find out!

Inventory Accuracy

Enhanced inventory accuracy is one of the critical advantages of choosing a cycle counting method. Occasions can be identified and rectified by regular counts of inventory items, offering a more efficient solution than the traditional complete physical inventory approach. This regular inventory count process helps maintain accurate inventory levels and streamline inventory management.

Improved Inventory Management System

Implementing cycle counting boosts inventory efficiency and strengthens your entire inventory management framework. By pinpointing inconsistencies and potential challenges within your inventory system, you can take proactive measures to prevent future mistakes.

Reduced Business Interruptions

Conventional complete physical inventories can significantly interrupt day-to-day business activities, leading to revenue loss and lowered productivity. Meanwhile, inventory cycle counting takes less time and allows you to focus on other aspects of your business.

Periodic Counting

This technique is quite similar to cycle counting but slightly more organized. Some businesses carry out periodic counts every three to six months to ensure the approach remains accurate.

Seasonal Counting

When specific seasonal trends change, the best inventory count technique is the seasonal method. For instance, a clothing business could carry out an inventory count towards the end of each season to ensure they have sold all planned products for that particular period and free up room for the next season’s stock. In addition, food establishments may opt for this counting process before items expire to avoid violating health codes.

Annual Counting

Performing an annual inventory count is customary for companies with minimal stock and es that don't use cycle-counting or all stock. Additionally, yearly inventories validate any inaccuracies within the system to claim a tax deduction. Furthermore, as the year ends, the firm conducts stock-taking, incorporating it into its financial statements and subjecting it to external audits for accuracy.

To learn more about How to Add Inventory in QuickBooks, refer this guide

Make Your Inventory Counting Flawless with PayTraQer

Whether managing your inventory with Excel or accounting software like QuickBooks and Xero, keeping accurate stock records is essential for running a successful online business.

PayTraQer connects and syncs your payments with QuickBooks and Xero. This way you can keep track of the financial transactions of all your inventories. PayTraQer easily connects your eCommerce and payment gateway with QuickBooks or Xero for immediate and precise synchronization. So, if you're looking at doing an inventory count soon, note the steps mentioned above for a more seamless experience!

If you want to learn more about finding marginal cost, check out this guide how to find marginal cost.

FAQs

What is the objective of inventory counting?

The primary goal is to ensure the accuracy of inventory records, verify stock levels, and identify any errors between physical stock and recorded amounts.

What are the benefits of stock count?

Stock counting helps maintain accurate inventory levels, reduces losses due to theft or spoilage, improves order fulfillment, and supports effective stock management.

What are the benefits of cycle counting?

Cycle counting offers continuous accuracy, minimizes disruptions to operations, enhances inventory management, and allows for more frequent corrections without needing a total inventory shutdown.

What is the best way to count inventory?

The best method varies by business needs but often involves a combination of cycle counting for ongoing accuracy and periodic total counts for comprehensive audits, using technology and inventory management software for efficiency.