A Complete Guide to Inventory Management Methods & Techniques – With Formulas and Pros & Cons

Managing inventory paves the road to retail success. We discussed this extensively in our guide to inventory management, along with the various steps involved in the process.

However, regardless of the size of your business, you should have an inventory management method that guides your entire supply chain operations. Here are some of the proven strategies and techniques to manage your inventory.

Contents

Just-in-time Management (JIT)

Materials Requirement Planning (MRP)

Economic Order Quantity (EOQ)

Day Sales of Inventory (DSI)

Cross-docking

Perpetual Inventory Management

Minimum Order Quantity

Safety Stock Inventory

Batch Tracking

Consignment Inventory

ABC Analysis

Reorder Point

Dropshipping

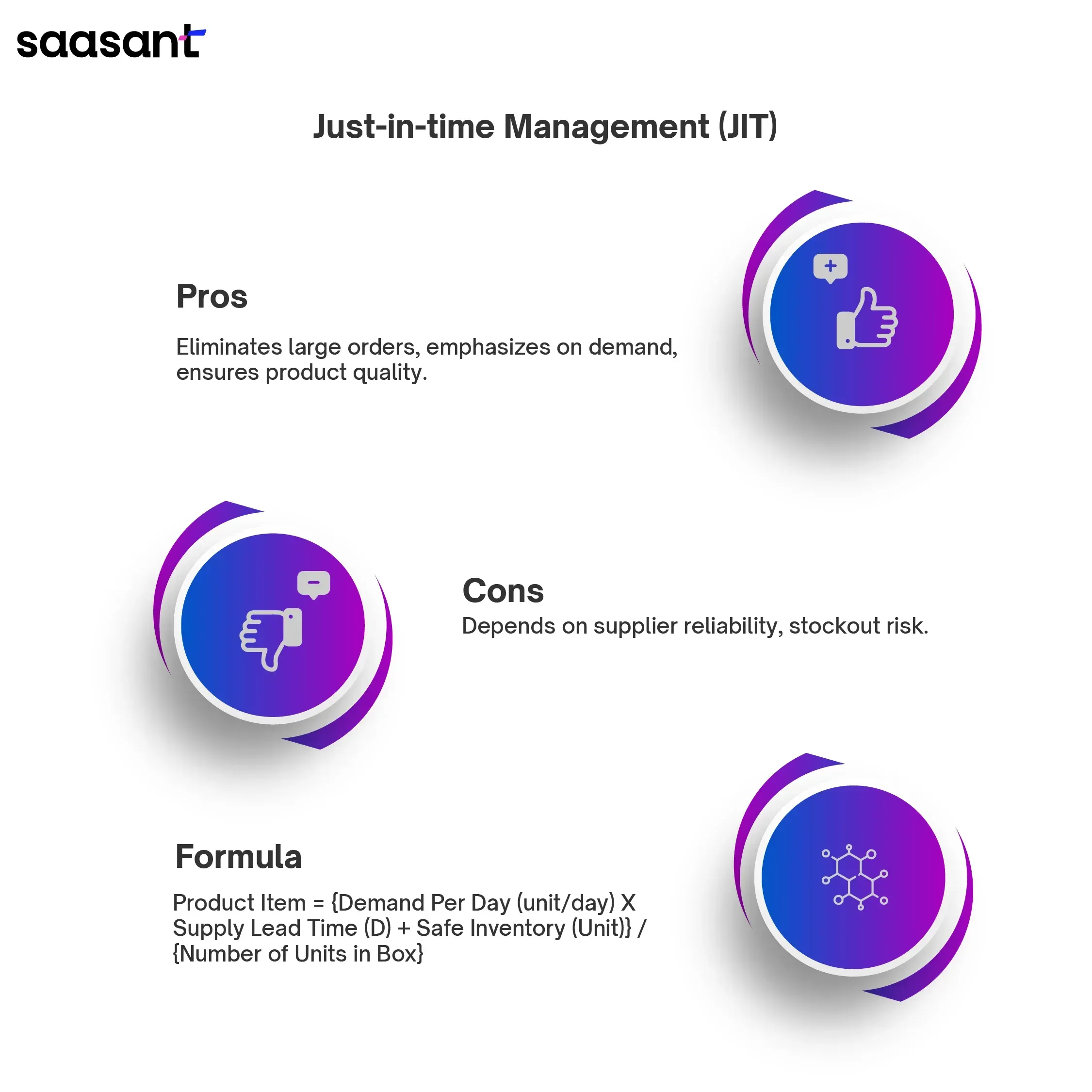

Just-in-time Management (JIT)

Just-in-time (JIT) inventory management is a strategy in which businesses maintain only a minimal amount of inventory, instead ordering and receiving new stock just as it’s needed to replace what has already been sold. This approach helps businesses reduce storage costs while keeping their products fresh and up-to-date.

Pros

Eliminates Large Orders - One of the most significant benefits of JIT inventory management is that it removes the need to stockpile large amounts of products and raw materials. By only ordering what you need when you need it, you can save on storage and warehousing costs while also reducing the risk of outdated or expired items.

Emphasizes on Demand - JIT systems are designed around real-time demand, so you can adjust your order quantities with greater accuracy—ensuring that you’re not ordering too much or too little for current customer needs.

Ensures Product Quality - Another advantage of JIT inventory management is that it allows businesses to focus on acquiring higher quality products at lower prices from reliable suppliers. It means that instead of finding low-cost options for large orders, companies can focus on finding the best supplier who meets their specific needs. This results in better deals on goods and improved product quality overall.

Cons

Depends on Supplier Reliability - JIT is highly dependent on how suitable your suppliers are. You’re left to trust in the reliability of your suppliers—if a shipment doesn't arrive on time, your entire system could come crashing down. So, communication between all parties involved (suppliers, buyers, etc.) must be timely and accurate.

Stockout Risk - When keeping low stock levels, businesses can easily be caught off guard if their product demand exceeds. It could result in a dramatic decrease in customer satisfaction should they experience out-of-stock incidents. So, companies opting to use the Just In Time (JIT) approach will need to make sure that both their production and supply chain management processes are operating as efficiently as possible with little room for error or delays.

JIT Formula

A standard JIT formula is:

Product Item = {Demand Per Day (unit/day) X Supply Lead Time (D) + Safe Inventory (Unit)} / {Number of Units in Box}

Here,

Demand Per Day - Refers to the demand for a product daily

Supply Lead Time - Refers to the time taken for the supplier to deliver the inventory

Safe Inventory - The amount of safe and undamaged inventory

Number of Units - Total number of units in a batch or box.

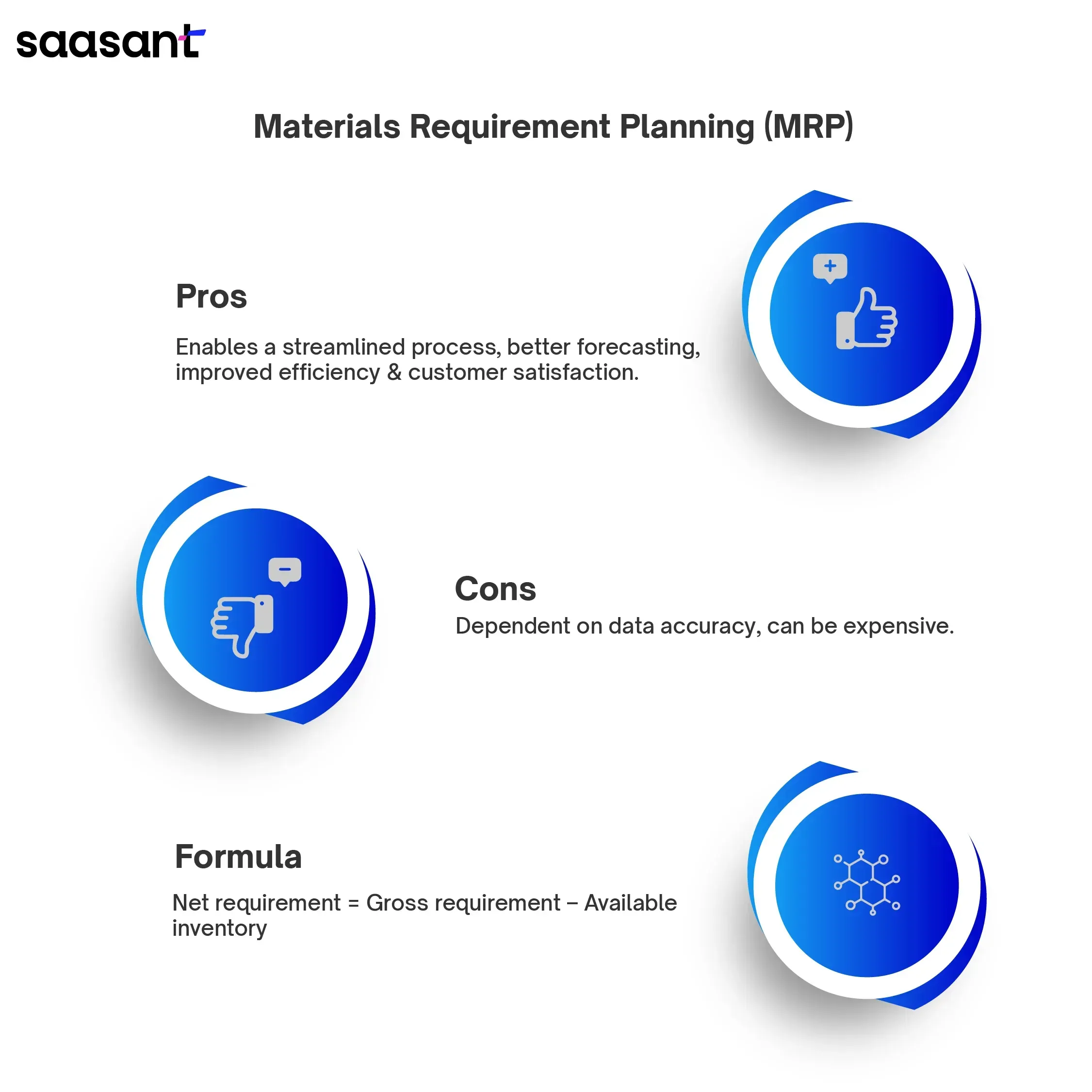

Materials Requirement Planning (MRP)

Materials Requirement Planning (MRP) is a system for effectively managing the materials required for production in a manufacturing environment. It uses the bill of materials (BOM) and the master production schedule (MPS) to calculate the quantity of each component needed to complete a finished product.

The MRP system allows manufacturers to plan their operations more effectively by considering both material availability and demand. It utilizes data accuracy, essential for accurate calculations, and considers factors such as delivery date information, lead times, safety stock levels, etc.

Pros

Enables a Streamlined Process - MRP functions by first breaking down a finished product into individual components or assemblies required in its production process. The system then identifies the amount of each element currently on hand to calculate any additional items needed to satisfy expected demand.

Better Forecasting - A suitable inventory management software enables better forecasting. MRP allows managers to determine their need for labor and supplies while assuring that all necessary materials are readily available when needed. It can dramatically reduce waste through improved efficiency in purchasing decisions and reducing costly delays in production due to inadequate inventories of parts or materials.

Improved Efficiency & Customer Satisfaction - MRP contributes towards better customer service through reduced lead times in the delivery of products. Improved visibility into material needs makes it easier for companies to identify products that require reordering or restocking components quickly; this enables them to respond faster when orders come in from customers, which ultimately leads to increased customer satisfaction with their experience doing business with the company.

Cons

Dependent on Data Accuracy - For MRP to operate optimally, data accuracy is essential. It typically requires extensive information collection procedures, such as entering data from suppliers and customers into the system.

Can be Expensive - Implementing an MRP system can involve significant costs in terms of time and money due to the manual input involved. Once the system is up and running, it can help create highly flexible production scheduling plans and adhere strictly to deadlines.

MRP Formula

The standard formula and procedure to calculate inventory requirement in MRP is as follows:

Net requirement = Gross requirement – Available inventory

The available inventory for the first period is

Available inventory = On-hand inventory + Scheduled receipts of the first period – Allocations – Backorders – Safety stock

And for the other periods

Available inventory = Projected available balance at the end of last period + Scheduled receipts of the current period.

Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) has been used extensively in the modern business setting since its invention in 1913 by Ford W. Harris.

An effective inventory management model that informs businesses precisely how many units they should purchase for each item whenever it needs restocking. Therefore, it minimizes inventory costs, such as order, holding, and shortage costs.

EOQ ensures that companies make orders sparingly or have too much excess inventory by establishing the ideal order quantity for each batch.

Pros

Cash Flow Tool: The strategic use of EOQ can be a robust cash flow tool, helping companies regulate and control the amount of money tied up in inventory. For many businesses, this is their most significant asset aside from human resources - so having sufficient stock to satisfy demand is essential. These savings can be reinvested into other areas or investments for further growth opportunities.

Better Fulfillment of Orders: EOQ helps businesses save money on ordering and shipping costs while ensuring that customer needs are always met. Companies can reduce their inventory orders without negatively impacting supply chain performance by calculating how much inventory should be ordered simultaneously for optimal efficiency.

Improves Discounts with Suppliers: Using EOQ helps reduce excess ordering and production waste by only ordering what is needed when it is required. Businesses may take advantage of supplier quantity discounts if they purchase more extensive inventories in one order.

Cons

Keeping Up With Data: Many companies need better data accuracy, leading to inaccurate EOQ calculations that do not accurately reflect demand patterns or cost structures. By default, the EOQ model assumes that consumer demand is constant without considering spikes in demand or when seasonal needs change significantly throughout the year.

Rapid Growth Limitations: Rapid business growth can quickly outpace an organization’s ability to maintain accurate inventory management techniques like EOQ as more resources become necessary to keep up with demand.

EOQ Formula

Here’s the formula to determine EOQ.

Q= √ 2DS/H

Where

‘Q’ = Number of units

‘D’ = Demand,

‘S’ = Cost per order, and

‘H’ = Cost of holding

Companies with complex supply chains and variable costs can tailor the EOQ formula to optimize production levels and order intervals.

Day Sales of Inventory (DSI)

Days Sales of Inventory (DSI) is a model used to measure the average number of days it takes for a company to convert its inventory into sales. It evaluates the liquidity of a company's inventory, showing how quickly the stock can be sold off and replaced with new items.

A low DSI suggests that the current customer acquisition, sales, and marketing strategies are effective. In contrast, a high DSI could indicate potential problems with the company's business model and target customer base.

Common issues that could lead to an inflated DSI include reduced consumer demand, excessive pricing, failing to meet customer preferences, and lagging behind competitors in pricing or product offerings.

Pros

Reveals Insights into Efficiency: Inventory turnover is an essential measure of a company's effectiveness in generating sales, but the day’s sales of inventory ratio take it even further. This metric gives organizations greater precision in their stock management and overall efficiency by providing insight into how fast the inventory moves daily.

Enables Informed Decision-Making: DSI helps companies make informed decisions regarding how much inventory they should keep on hand and when and how often they should restock their shelves. Generally speaking, a lower DSI is preferred since it indicates that a company has been able to quickly sell off its inventory and replace it with new products.

Cons

Requires Regular Monitoring: It is crucial for companies to regularly monitor their DSI figures to identify potential opportunities for improvement. For example, suppose the company finds its current DSI too high. In that case, they must increase promotion efforts, diversify product offerings, or even reduce prices if necessary.

Reliant on ICP’s Preferences: DSI requires understanding your customer preferences. It requires researching target customers thoroughly to understand their spending habits better. If you get incorrect info or limited market research data on your ICP, it may greatly affect sales.

DSI Formula

The calculation for DSI involves taking the average balance of total inventory during the period and dividing it by the cost of goods sold during the same period divided by 365.

The formula:

Days Sales in Inventory (DSI) = (Average Inventory ÷ Cost of Goods Sold) × 365 Days

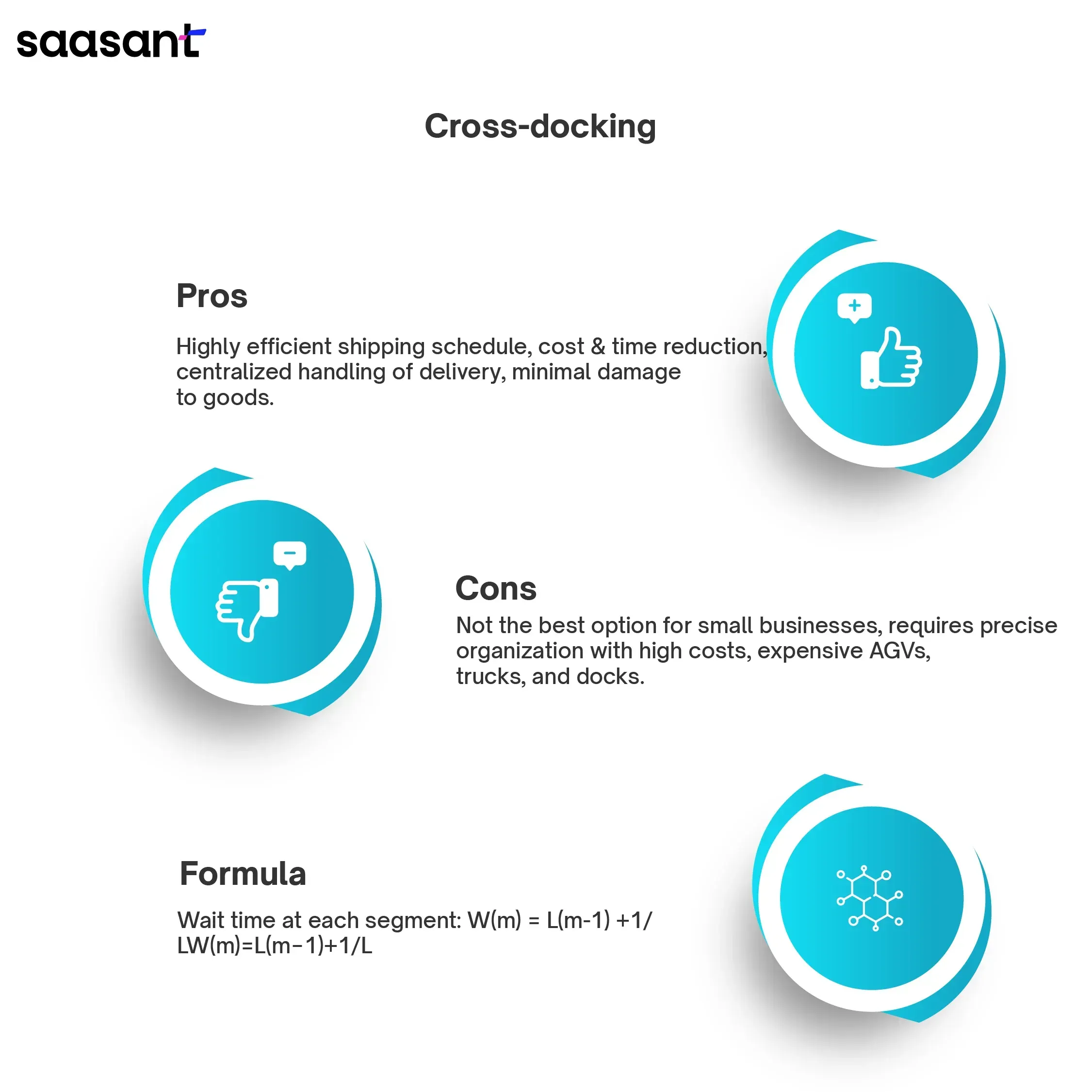

Cross-docking

Cross-docking is a robust inventory management system that reduces time and expense connected with warehousing. Rather than passing merchandise through intermediate storage and handling, this inventory system approach sends goods straight from the manufacturer or supplier to customers or retailers through this inventory system.

In cross-docking, finished goods are moved into inbound docks immediately after they’re unloaded from incoming transport (from the supplier). These items are sorted and consolidated at the terminal before being loaded onto an outgoing vehicle (to the customer or retailer) at the outbound dock.

With this process, you don't need to worry about long-term or even short-term warehousing and can rest assured that your replenishment times will be as fast and cost-efficient as possible.

This form of lean logistics can quicken retail fulfillment activities for large orders and reduce shipping costs by positioning stock closer to final purchasers.

Pros

Highly Efficient Shipping Schedule: Through cross-docking, goods can promptly reach their final destination as the labor usually used to store merchandise is significantly reduced or eliminated. As larger batches are split into smaller shipments and loaded onto freight vehicles traveling in the same direction, shipping effectiveness rises sharply. It leads to a much faster transit time and improved customer satisfaction overall.

Cost & Time Reduction: COGS is a substantial element of inventory expenses, and by cross-docking, businesses can avoid additional logistics charges linked with storing goods in warehouses, such as rent costs and salaries for staff members. It allows companies to cut their capital spending significantly. Furthermore, centralizing the delivery process optimizes time savings through automation processes.

Centralized Handling of Delivery: Using a centralized cross-dock warehouse, the last-mile delivery of goods is optimized to reduce congestion and improve supply chain efficiency. Rather than having numerous vendors and distributors sending their products independently to various locations, consolidating them in one central area allows for streamlined flow with fewer disruptions.

Minimal Damage to Goods: Additionally, by utilizing this system, the time for processing shipments is cut significantly, and all goods are securely transferred, ensuring that they reach their destination on time with minimal damage.

Cons

Not The Best Option for Small Businesses: If a company's inventory turnover rate is projected to increase significantly later, cross-docking and its accompanying tracking technology might not be the most cost-efficient solution due to its high overhead costs.

Requires Precise Organization with High Costs: To engage in an effective cross-docking operation, firms must have advanced technology, streamlined operations, and rapid staff; unfortunately, this type of setup can be costly to establish.

Expensive AGVs, Trucks, and Docks: Transitioning to a cross-docking system can be costly as it requires large-scale purchases of trucks, AGVs (Automated Guided Vehicles), and other cargo carriers. Furthermore, additional space outside your warehouse is needed to house these vehicles if you plan on owning them instead of outsourcing them.

Cross-docking Formula

Mean Value Analysis is one way to estimate throughputs quickly, wait times rapidly, and queue lengths in a cross-dock travel system.

Here are the formulae related to Cross-docking using Mean Value Analysis:

Wait time at each segment:

W(m) = L(m-1) +1/ LW(m)=L(m−1)+1/L

System throughput for m AGVs:

λm = m/ (∑ W(m)∗v)λm=m/(∑ W(m)∗v)

Average Queue Length at each segment:

Queue Length = vλmW(m)Queue Length=v∗λm∗W(m)

Here,

Segment refers to each inbound door of the cross-dock

‘L’ represents the queue lengths of each segment

‘m’ represents the number of AGVs

‘v’ represents the visit ratio.

AGV represents Automated Guided Vehicles

λ the throughput value

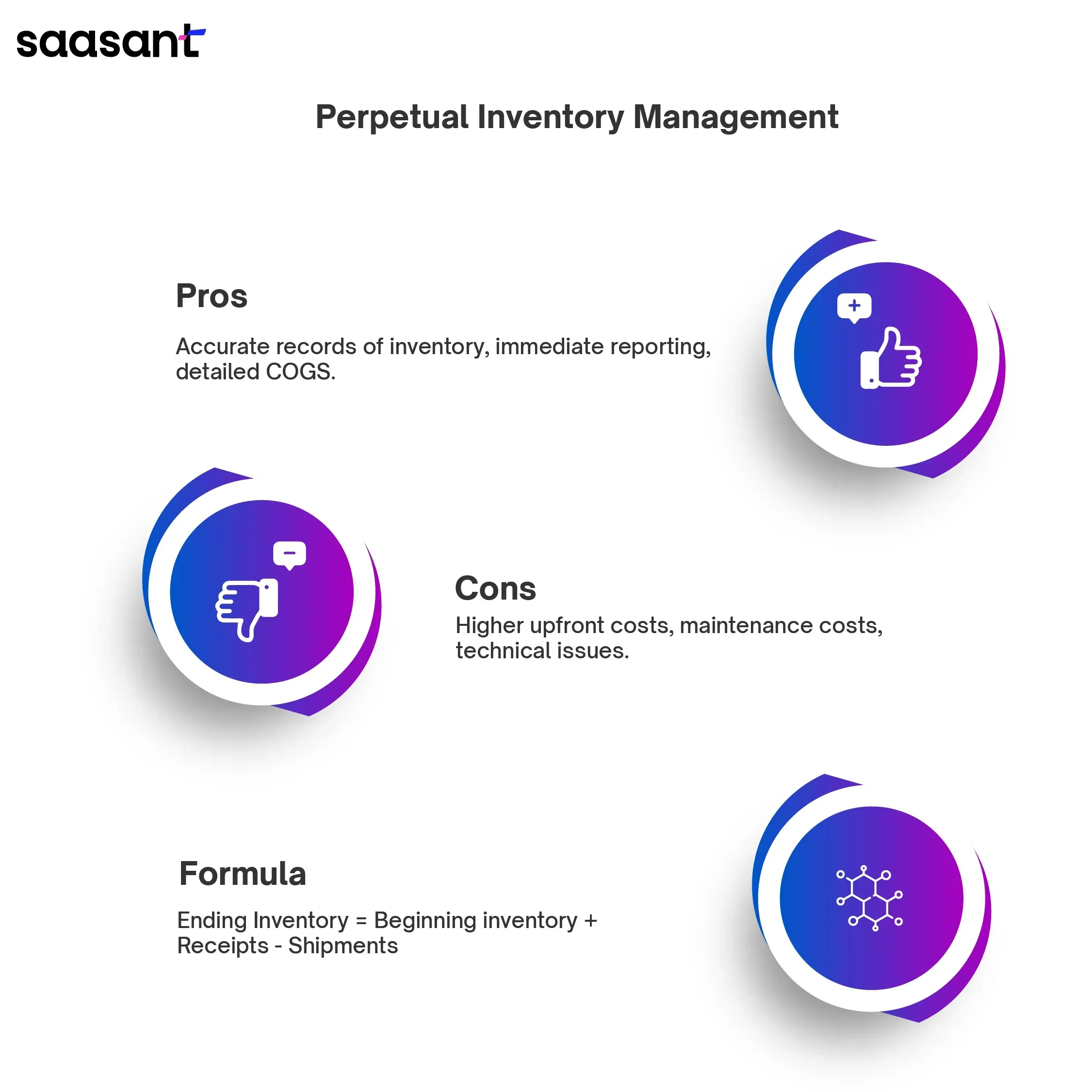

Perpetual Inventory Management

Perpetual inventory management is an accounting system with advantages for e-commerce businesses of all sizes. This inventory tracking method monitors and updates stocks continuously as sales occur.

It uses computer-based point-of-sale systems to record these changes in real-time, significantly lowering the cost of traditional inventory audits. It makes it an attractive option for businesses seeking to streamline their operations.

In a perpetual system, the general and inventory ledgers are updated in real time with each transaction.

While initial investments may be costly, these costs can oftentimes be offset in the long term by reduced labor costs associated with manual counting procedures.

For example, in a LIMS, perpetual inventory management empowers precise tracking of sample tubes in real time, volumes, and storage locations, ensuring chain-of-custody integrity and automatically flagging when precious samples fall below defined thresholds.

Pros

Accurate Records of Inventory: Perpetual inventory management provides accurate records of goods on hand at any given time through real-time data updates. It also helps eliminate labor costs associated with manual stocktaking and corrects errors due to human error or theft.

Immediate Reporting: With this system, a company can track changes in inventory with immediate reporting on the amount of items currently in stock without needing detailed records or physical counting of items. In addition, it creates an audit trail that can provide valuable insights into how items are moving throughout the supply chain, allowing business owners to identify bottlenecks and optimize their internal processes.

Detailed COGS: This system provides businesses with a more detailed cost analysis when calculating their cost of goods sold (COGS). Direct materials and labor costs are automatically accounted for in the perpetual system, as are direct factory overhead costs such as utilities and maintenance fees. These details allow companies to more accurately assess profitability from product sales and make better decisions about pricing strategy or staffing needs.

Cons

Higher Upfront Costs: As mentioned earlier, the upfront cost can be high since it requires software and hardware investments and installation fees for point-of-sale systems if they don’t already exist within a business’s infrastructure.

Maintenance Costs: Monitoring maintenance isn’t included in the initial setup, so regular checks must be conducted by IT personnel or a third-party service provider to keep up data accuracy levels over time and ensure no issues arise from software glitches or customer misuse of POS systems.

Technical Issues: There may be reliability problems if the server crashes or other technical issues that prevent data from being appropriately recorded at specific intervals throughout a business day – which could result in inaccurate inventory counts if not addressed promptly enough.

The Formula for Perpetual Inventory Management

A standard formula used to calculate the ending inventory

Ending Inventory = Beginning inventory + Receipts - Shipments

Another formula that’s associated with this system is the COGS formula:

COGS = Beginning Inventory + Purchases - Ending Inventory

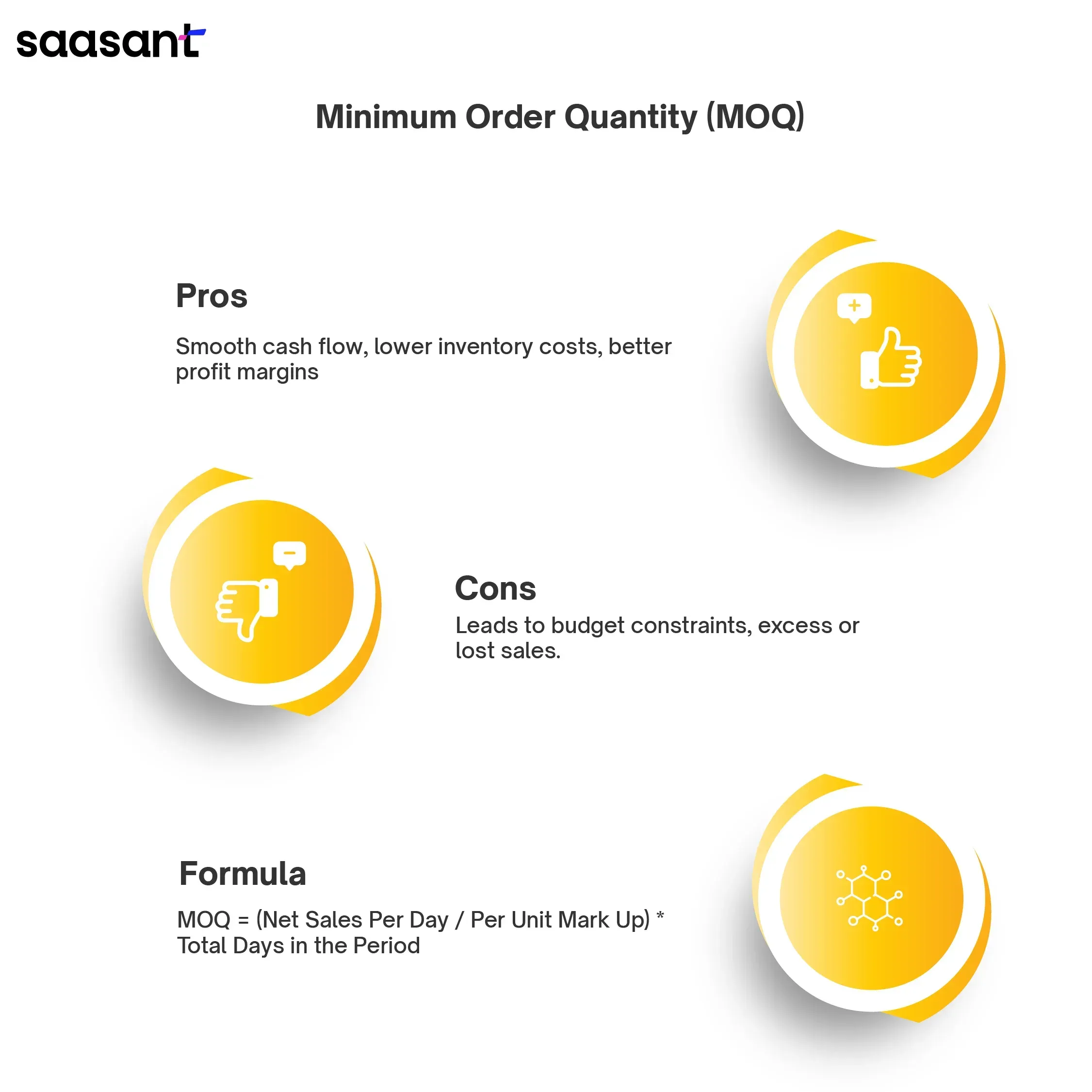

Minimum Order Quantity

Minimum order quantity (MOQ) is a common requirement set by suppliers that can significantly impact the profitability of any business.

In some industries, such as electronics, MOQs can range from hundreds to thousands of units, depending on the product. On the other hand, for fast-moving consumer goods like apparel and groceries, an MOQ may only be a few dozen or a hundred. While there are many advantages to setting an MOQ, it also comes with a few drawbacks.

Pros

Smooth Cash Flow: The primary advantage of setting an MOQ is better cash flow. By anticipating their costs in advance and setting their MOQs accordingly, businesses can ensure that they’ll reach their desired profit level and have more predictable income streams.

Lower Inventory Costs: Instead of buying large quantities of stock upfront and storing them until sold, suppliers can manufacture products only after orders come in and reduce their storage costs significantly.

Better Profit Margins: Minimum order quantity helps increase profit margins by encouraging suppliers to produce goods when sales levels create profitable operations.

Cons

Leads to Budget Constraints: One of the significant drawbacks of minimum order quantity is that it often prevents smaller businesses from purchasing certain products due to prohibitively high prices for large quantities. It makes it difficult for smaller companies and entrepreneurs to buy supplies needed to run their businesses efficiently or even get started in the first place.

Excess or Lost Sales: If businesses overestimate demand for certain products when setting MOQs or underestimate demand for others, there could be financial losses associated with excess supplies or lost sales opportunities due to lack of stock.

Minimum Order Quantity Formula

The formula is:

MOQ = (Net Sales Per Day / Per Unit Mark Up) * Total Days in the Period

Here,

Net Sales Per Day refers to the number of product SKUs you must sell monthly.

Per Unit Mark Up refers to the profit margin retailers add to the cost price of a product.

Total Days in the period refer to.

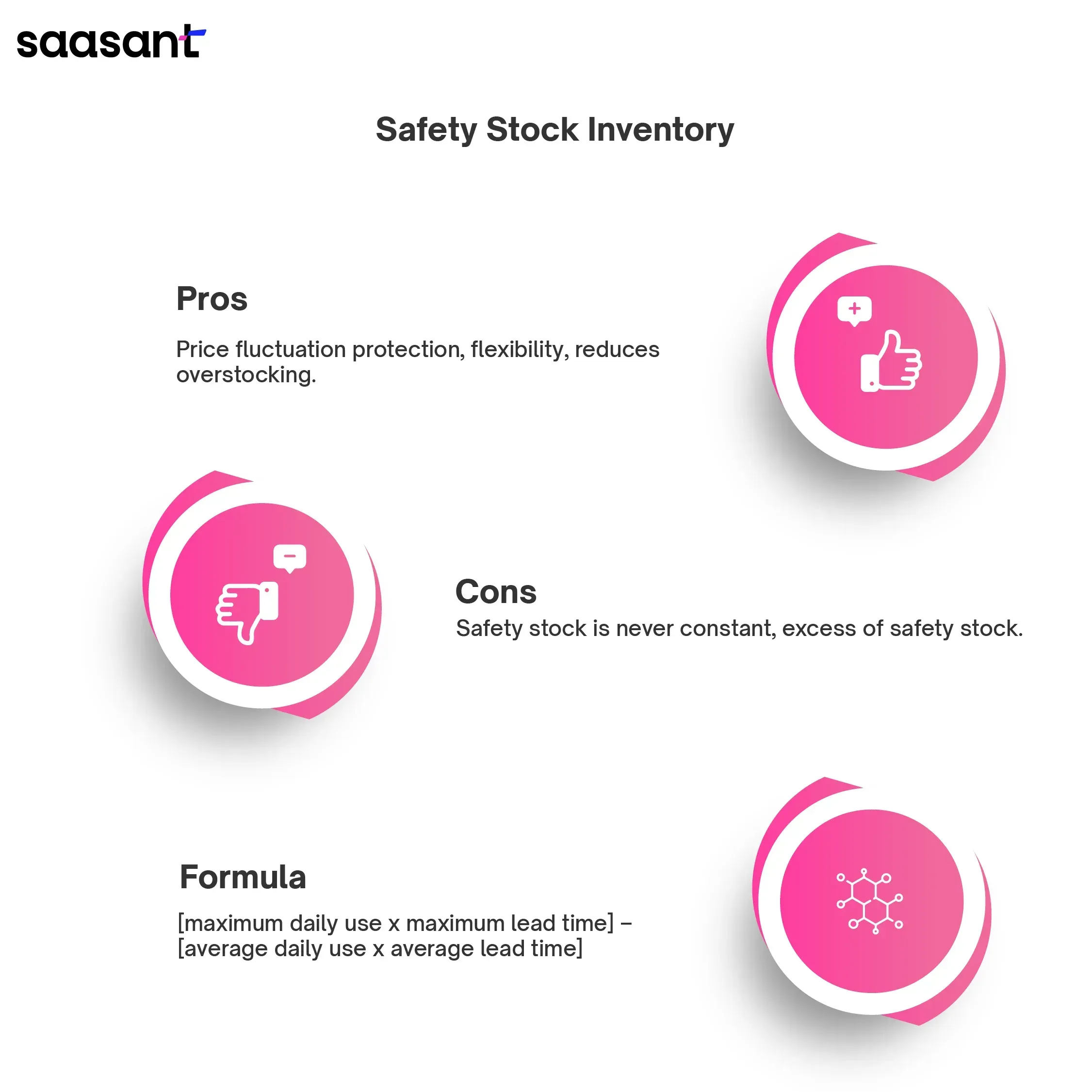

Safety Stock Inventory

Safety stock inventory management enables businesses to maintain a steady level of product availability and helps them remain competitive in the market.

Safety stock can protect against potential inventory shortages, uncertainty in demand or lead times, and unexpected price fluctuations. It also serves as a buffer against errors in forecasting and ensures customer satisfaction by avoiding stockouts and delivery delays.

Managing safety stocks requires a skillful balancing act between managing risks associated with stockouts while minimizing costs related to extra inventories - something that requires careful planning and accurate forecasting capabilities.

Pros

Price Fluctuation Protection: When market volatility strikes, it can cause the price of your products to skyrocket without warning. It might be caused by a shortage of resources, sharp increases in raw material costs, an influx of demand from buyers, fresh contenders entering the market, or government regulations shaking things up. Having emergency reserves is essential to avoid paying exorbitant prices for stock and still not compromise on sales figures during such unexpected scenarios!

Flexibility: The primary benefit of this method is that it provides companies with more flexibility when dealing with uncertain demand, delivery delays, and other external changes. With an extra inventory in reserve, businesses can quickly fulfill any sudden orders or address any supply chain disruptions.

Reduces Overstocking: Having an appropriate amount of safety stock can reduce the chances of overstocking by allowing companies to anticipate customer demand better and adjust their levels accordingly.

Cons

Safety Stock Is Never Constant: As your business grows, more than the existing safety stock may be required. Therefore, it is imperative that inventory managers continually evaluate potential bottlenecks and adjust safety stock levels accordingly. It will ensure that all of your operations remain at optimal performance throughout each stage of development.

Excess of Safety Stock: Having reserves of safety stock is often necessary to ensure that customers don’t experience a shortage of products, yet it significantly decreases the amount of accessible cash for businesses. Excess safety stock can mean fewer resources for existing cycle inventory or new items.

Safety Stock Formula

The formula to calculate safety stock formula is:

[maximum daily use x maximum lead time] – [average daily use x average lead time]

Batch Tracking

Batch tracking inventory management is a system that traces parts and ingredients connected to a group of products, from raw materials to finished goods, throughout their entire journey in the distribution chain.

It is becoming increasingly popular in the modern supply chain management system.

Businesses can track individual batches of products with serial numbers or dates that indicate when the product was manufactured or when it will expire.

Pros

Real-time Visibility: Through batch tracking, businesses can gain real-time visibility into their inventory and enable strategic decision-making. It improves efficiency by providing real-time visibility into your inventory. It helps reduce wastage by organizing your inventory according to your needs and requirements.

Quality Control: It enhances quality control as you can keep track of expiration dates, facilitate the real-time tracking of sample units for testing, and trace other issues related to specific suppliers. Batch tracking also helps improve health and safety by ensuring that only fresh products reach customers.

Reduces or Eliminates Human Error: It eliminates human error as you no longer need to manually track inventory manually, reducing common shipping mistakes such as sending out incorrect product components.

Cons

Requires Training Your Staff: Training personnel on using batch tracking correctly may also be necessary depending on its capabilities, which could add further cost if outside help or expertise is required.

Time-Consuming at the Beginning: The process can be time-consuming as there is a need for careful record-keeping of each item's batch numbers and expiration dates. Additionally, record inaccuracies can lead to incorrect usage or shipment of expired items, resulting in customer dissatisfaction and possibly legal action against the business if things go too far.

Consignment Inventory

Consignment inventory management can be an excellent way for retailers to grow their business and improve their inventory selection without taking too much financial risk.

With this model, the consignee (i.e., the retailer) only has to pay for goods once sold. The consignor (i.e., wholesaler, supplier, or manufacturer) retains ownership of the products. This arrangement provides a beneficial opportunity for both parties and can provide many advantages when done right.

Pros

Minimal Financial Risk: Retailers don’t have to pay out any capital upfront, giving them more flexibility with their finances while ensuring they can still access merchandise that customers are interested in buying.

Increase in Sales: Consignment also offers a potential increase in sales as it can add breadth and depth to retail inventories, allowing retailers to expand their offering beyond what they could manage with their own money alone.

Cons

In-store Stocking Expense: While there may be no upfront costs for consigned goods, stocking them in-store comes with additional expenses, such as higher carrying or holding costs, due to having an extra layer of management involved in tracking these items. As a result, retailers need to factor these costs into their budgeting process before taking on this type of agreement.

Multiple Delivery Schedules: Managing consigned goods can be more complex than managing standard goods due to different delivery schedules and other logistical challenges that pop up along the way.

A Few Honorable Mentions

ABC Analysis

ABC analysis is an inventory management technique that classifies items based on their importance to the business. It assigns priorities, focuses attention and resources on the most valuable items, and ensures that scarce resources are allocated accordingly.

The ABC method ranks items according to demand, cost, and risk data, from which inventory managers group them into classes based on those criteria.

Class A items are SKUs with the highest sales volume or profitability, making them the most important for a business's success. Class B typically includes the second-most important SKUs regarding sales volume or profitability, while Class C comprises all other SKUs.

By grouping products into these three classes, managers can easily organize inventories to prioritize critical stock-keeping units (SKUs).

Although related, ABC analysis in cost accounting (activity-based costing) differs from using this same technique for inventory management. Specifically, accountants employ activity-based costing to allocate indirect expenses such as salaries and utilities to products and services produced by a manufacturing business.

Reorder Point

A reorder point (ROP) is the minimum inventory level businesses must maintain to ensure they can fulfill customer orders without running out of stock. If the stock falls beyond this level, then a reorder to replenish the stock will be placed.

When determining a reorder point, businesses should consider factors such as customer demand, order lead times (the time it takes for your vendor to supply items), safety stock (the additional amount of stock maintained above a required level of availability), and other variables.

These elements are essential when deciding the right time and quantity to order new stock. They should also consider seasonal variations in customer demand or any expected changes in lead times when creating their reorder points.

Reorder Point Formula

The formula to create ROP is:

ROP = (daily average usage X lead time) + safety stock

Dropshipping

Dropshipping is an excellent way for retailers to save on inventory management costs without carrying physical stock. With this method, you purchase the goods from your supplier and advertise them on your store or marketplace platform. When a customer orders something, the supplier partner packages and ships it directly to the customer. It allows entrepreneurs and new businesses to take advantage of a low-risk method of selling products since there's no need to manage physical inventory. It’s great for startups and works well as your business grows - allowing you to scale and add this method alongside other fulfilling methods. These are the various inventory management methods that business owners, both small & big, can use to manage their inventory effectively.

QuickBooks is a popular accounting software that can be integrated with dropshipping businesses to streamline financial management. It lets you manage inventory levels in real time.

QuickBooks also offers features like automatic invoicing, tax calculations, and financial reporting, making it an ideal tool for dropshipping businesses. Integrating QuickBooks with your dropshipping business helps you track sales, expenses, and fees, saving time and reducing errors so you can focus on growth. Use SaasAnt Transactions to import orders and payouts in bulk, apply rules for fees and taxes, and reconcile at scale, and pair it with PayTraQer to sync e-commerce platforms and payment gateways into QuickBooks in near real time for clean, consistent books.

If you want to learn more about finding marginal cost, check out this guide how to find marginal cost.

To learn how to enter inventory in QuickBooks, refer to this guide.